What is MPO Connector?

MPO is short for “Multi Fiber Push On”. It was developed to provide multiple fiber connections in one connector to support higher bandwidth and higher density applications.

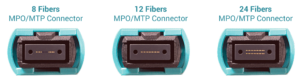

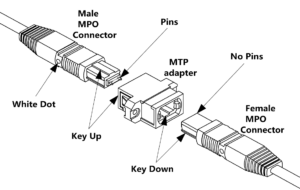

There are 2 versions, male (pinned) and female (pinless). The most common fiber counts are currently 12 and 24. 48 to 72 are possible but have limited applications. The next format will be 16 and 32 fibers, which are required for 400Gb applications.

What is the Difference Between MPO and MTP Connectors?

- The MTP connector is a high performance MPO connector designed for improved mechanical and optical performance.

- The MTP connector housing is removable. This feature allows for the MT fixture to be reworked and repolished, or even gendered in the field after assembly, or the zipper to be interferometrically scanned after assembly.

- The MTP connector features a ring float to improve mechanical performance. This allows the mated pair to maintain physical contact when under an applied load.

- The MTP connector features a metal pin clamp that is used to center the thrust spring. This feature: Centers the spring force and eliminates fiber damage seen in the spring.

- A plastic pin clamp and round spring are used in MPO, while a metal pin clamp and oval spring are used in MTP.

- Pin hole damage occurs in 50 matches in MPO, while this number is approximately 500 in MTP.

Why MPO Connector, What Are Its Advantages and Disadvantages?

The rapid increase in the number of network connections in data centers can cause traditional fiber cables to become congested and difficult to manage in the data center. To solve this problem, data centers must achieve ultra-density to accommodate all the cables used in cabling.

MPO/MTP cables, which combine 8, 12, 24 fibers in a single interface, have proven to be a practical solution. The connectors of MTP/MPO multi-fiber cables are the same size as an SC connector to meet the 40GBASE-SR4 and 100GBASE-SR10 standards, but can accommodate 8, 12, 24 fibers, thus saving circuit, card and rack space

Disadvantage: Very sensitive and difficult to clean surface

How to Connect MPO Cables?

When creating an MPO connection, a male and a female connector and an MPO adapter are always used. Never connect a male to a male or a female to a female.

If a female-female connection is made, the pins of both connectors will not be exactly the same height, which will cause a loss of performance. If a male-male connection is made, the pins of the two connectors will hit each other, so contact cannot be established and the connectors may be damaged.

How to Measure MPO Cables and Understand Their Quality?

- After MPO cables are produced, they are cleaned and monitored both microscopically and geometrically from devices to ensure their quality and cleanliness.

- Then, measurements are made with VIAVI’s MPO test device to check light transmittance and whether the fibers meet standard values.

- In MPO measurement, 1 Jumper cable fixed to the device, 1 Master cable determined depending on the type of cable we will measure and the actual cable we will measure, called DUT, are used.

- Before measurement, the cleanliness of the cables to be used is ensured and the master cable is taken as a reference for measurement. Then the measurement cable is connected to the master cable and the device and the measurement is performed.

- The measurement result is reported with the final results.

Is MPO Cable Produced in Türkiye?

MPO cable is produced for the first time in Turkey at SAMM TEKNOLOJİ.