The Importance of Cleaning MPO or MTP Connectors

Nowadays, high-density fiber optic networks are becoming the main stream around the world and multi-fiber MPO and MTP connectors are becoming the dominant type of connectors used in high-density networks. Consequently, connector uncleanliness has become the most common cause of network failure. Even if an MPO/MTP connector was cleaned before making the connection, improper cleaning might give poor results and not as expected. Therefore, MPO/MTP connector inspection and cleaning using the right methods and tools is very important.

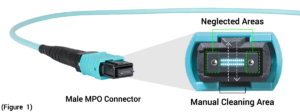

Cleaning MPO/MTP connectors is a bit trickier than most users may believe. MPO and MTP connectors have multiple fibers with a wide contact surface, and any bit of dirt on one fiber can cause signal degradation in the rest of the fibers in the connector. In addition, due to the presence of alignment pins in the male connectors, cleaning the end sides of the MPO/MTP connector surface is often overlooked by users (Figure 1). Thus, when cleaning an MPO/MTP connector, all fibers in the connector must be cleaned thoroughly to ensure proper operation; and having repeatedly cleaned a connector does not ensure reaching the expected results unless the right cleaning method is actually used.

MPO/MTP Connector Cleaning Methods

The first step is a connector ferrule surface inspection. Before a connector is cleaned, it should be viewed with a fiber optic microscope in order to decide whether it needs to be cleaned or not. If cleaning is required, dry cleaning with a fiber cleaning special towel is usually the preferred and most effective method. Dry cleaning removes dirt and finger smudge without the possibility of leaving any remains on the fiber, unlike using alcohol-based cleaning products. Moreover, the area around the male connector pins must always be cleaned also.

Sometimes dry cleaning method does not seem to be enough to completely clean a certain connector. After the first cleaning attempt, a second inspection must be done to assess the new condition of the connector. If it is determined that the MPO/MTP connector is still somehow dirty after the second inspection, it is recommended to use the wet + dry cleaning method for a second cleaning, using proper alcohol-based cleaning products. After that, it must be inspected again and cleaned again using the wet + dry method if necessary. If the process is repeated too many times and the result is still negative that might mean the connector is permanently damaged and needs to be replaced. However, the cleaning process must be done very carefully and it should not be the cause of any permanent damage on the connector.

Using an MPO Cleaner Tool

Proper cleaning of an MPO/MTP connector with dedicated tools is the most guarantied and the quickest method. When using an MPO cleaning tool, one click should do the trick, because these cleaners are designed to fit the fiber funnel surface and clean it evenly. In addition, the MPO Cleaner tool can also clean MPO adapters, which makes it the perfect choice for network systems with multiple usages of MPO adapters. On the other hand, although is it a One-Click cleaning process, these MPO/MTP cleaners can do up to 600 cleaning attempts.