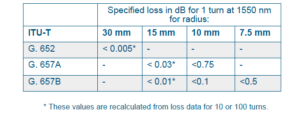

Specified bending losses for ITU-T G.652 and G.657 fibers

Optical Fiber and Cable Standards

Leading standardization bodies for:

Fibers:

ITU-T SG15:

- G650 test method series

- G651 multimode 50/125 μm

- G652 dispersion unshifted singlemode optical fiber

- G653 dispersion shifted singlemode optical fiber

- G654 cut-off shifted singlemode optical fiber

- G655 non-zero dispersion-shifted singlemode optical fiber

- G656 non-zero dispersion-shifted singlemode fiber for wideband optical transport

- G657 bending loss insensitive singlemode optical fiber

- Recent changes seen in G657 for low bend loss fibers

- FO Cables: IEC SC86A

- 60793 series for fibers

- 60794 series for cables

- Recent changes seen in patchcord cables IEC 60794-2-50

Low Optical Bend Loss Fibers

Why needed?

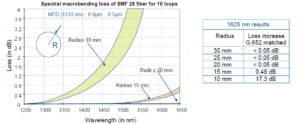

Bending loss performance of standard singlemode fiber (ITU-T G. 652D)

Observations:

- Loss becomes important once bending radius becomes smaller than 20 mm

- Splicing trays with 25 mm and 30 mm bending radius will not affect transmission at 1625 nm in G. 652D fibers

- In some limited cases (max 2 meter) a 20 mm radius is allowed (see ITU-T L13 and IEC 61756)

Low Optical Bend Loss Fibers

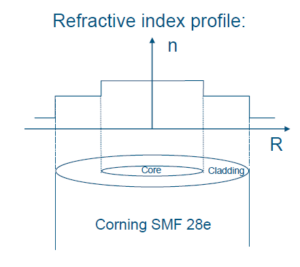

The traditional ITU-T G. 652D singlemode fiber Matched cladding

General:

Optimized bandwidth for 1310 nm transmission

(= Minimum chromatic dispersion at 1310 nm)

Lowest attenuation at 1550 nm

Characteristics:

Mode field diameter at 1310 nm: 9.2 μm ± 0.4 μm

Mode field diameter at 1550 nm: 10.4 μm ± 0.5 μm

Cladding diameter: 125 μm ± 0.7 μm

Mode field concentricity error: 0.5 μm @ 1310 nm

1550 nm loss performance: < 0.05 dB for 100 turns

on 50 mm mandrel diameter

Chromatic dispersion: 3.5 ps/(nm.km) @ 1310 nm

18 ps/(nm.km) @ 1550 nm

Proofstress strain test: 1%

Attenuation: <0.35 dB @1310 nm and <0.25 dB @ 1550 nm

Non colored coating diameter: 245 μm ± 10 μm

Colored coating diameter: 250 μm ± 15 μm

General:

Optimized bandwidth for 1310 nm transmission

(= Minimum chromatic dispersion at 1310 nm)

Lowest attenuation at 1550 nm

Characteristics (not up-to-date!):

Mode Field Diameter at 1310 nm: 8.8 μm±0.5 μm

Mode field diameter at 1550 nm: 9.7 μm ± 0.6 μm

Cladding diameter: 125 μm ± 1.0 μm

Mode field concentricity error: 0.8 μm @ 1310 nm

PMD (fiber): 0.5 ps/ km at 1310 nm

Chromatic dispersion:

18 ps/(nm.km)at 1550 nm

1550 nm loss performance: < 0.1 dB for 100 turns

on 75 mm mandrel diameter

Proofstress strain test: 1%

Attenuation: <0.4 dB @1310 nm and <0.3 dB @ 1550 nm

Non colored coating diameter: 245 μm ± 10 μm

Colored coating diameter: 250 μm ± 15 μm

Low Optical Bend Loss Fibers

How can you improve the bending loss performance?

Light in a waveguide is better “contained” when the difference of refractive index between the core and cladding is increased.

This results in a better bend loss performance, but it will result in a lower bandwidth or transmission capacity (modal dispersion, higher chromatic dispersion)

Different low microbend loss fiber types

ITU-T G. 657 recommendation

- ITU has published in Dec 2006 a recommendation for such fibers:

- ITU-T G.657A fiber: These are G. 652D fibers with tighter dimensional tolerances that will result in a better optical performance during bending. These fibers are also known as Low Macrobend Loss fibers. The specified minimum bending radius for optical attenuation is 10 mm. Roughly 10 times better bending performance than traditional single-mode fiber

- ITU-T G.657B fiber: Fibers designed to have a very low loss during bending, but they are not always compatible with the G. 652 fibers anymore and therefore restricted to shorter distances (associated with indoor cabling). These fibers can have connection and splicing problems for some types. These fibers are typically called Bend Tolerant Fibers. The specified minimum bending radius for optical attenuation is 7.5 mm. Roughly 100 times better bending performance than traditional single-mode fiber.

Different commercial available brand names

- Corning: RC HI 1060 Flex

- Corning: RC-SMF 28 with reduced cladding diameter (80 μm)

- Sumitomo: Pure access ultra

- Mitsubishi cable: Diaguide PCF (holey fiber type)

- OFS F900x series

- Nufern 1550-HP

- Corning SMF28e+

- Corning SMF28-XB

- Draka Comtec: BendBright

- Draka Comtec: BendBright XS

- OFS Allwave Flex

- Corning Clearcurve

- OFS EZ Bend

…. Many more …

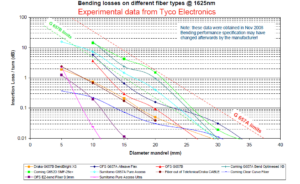

Low Optical Bend Loss Fibers

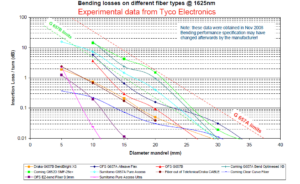

Experimental data from Tyco Electronics

But after 2006, fiber manufacturers have developed fiber types that even exceeds the bending loss performance of the G.657B! A minimum bending radius of 5 mm is possible without significant optical loss! Such fibers can be called a true Bend Insensitive Fiber.

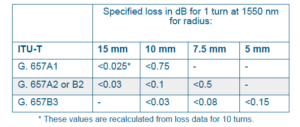

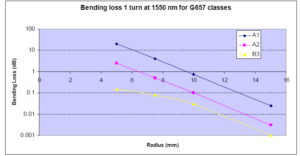

Specified bending losses in new ITU-T G.657

4 classes defined in the new ITU-T G.657 (be aware that this is still a draft!):

G. 657A1: these are G. 652D compatible fibers with specified minimum bending radius of 10 mm (same as previous G.657A)

G. 657A2: these are G. 652D compatible fibers with specified minimum bending radius of 7.5 mm

G. 657B2: these are not G. 652D compatible fibers with specified minimum bending radius of 7.5 mm

(same as previous G. 657B)

G. 657B3: these are not G. 652D compatible fibers with specified minimum bending radius of 5 mm

Mechanical reliability concerns

- During production fibers are screened with a 1% strain (or 0.7 GPa or 100 kpsi) test.

- A fiber bend with a 6 mm radius will have about 1% strain stress at the outside of the cladding.

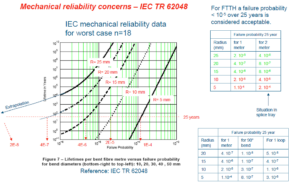

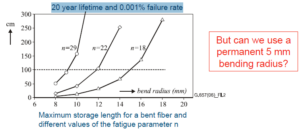

- The new ITU-T G.657 proposal document also deals with fiber lifetime considerations (in Annex I). Important :The accepted probability for fiber failures in the FTTH distribution part is around 1/100000 over 20 years per fiber per network element. However, the document does not state that a 5 mm storage radius can be used in a reliable way! Knowledge of the network layout is very important when deploying such low storage radii.

Specified bending loss values in ITU-T G.657

Mechanical reliability concerns – ITU-T G.657 Annex I

In the datasheets for fibers a parameter n is specified (n= the stress-corrosion susceptibility parameter or fatigue resistance parameter). This parameter is derived from a log (stress) versus a log (% cumulative failure) plot. The IEC 60793-2-50 standard for fibers specifies a minimum value of 18. Corning SMF28+ specified n=20 (which means better resistant to longterm bending)

In ITU-T G.657: Annex I

20 year lifetime and 0.001% failure rate

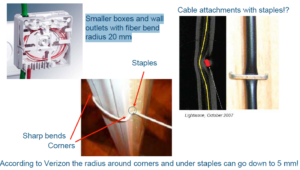

Mechanical reliability concerns

Installation inside houses:

Assume cable is routed though 3 rooms on the 1st floor:

- This results in about 15x 90° turns around a corner

- When nails or staples are used every 30 cm, about 70 staples will be used in this example. Assume that each staple or nail creates a bend with radius 5 mm over 15°

- In total 2 meter of fiber is stored in the floor distribution box and wall terminal with radius 15 mm

Important:

– In this case the estimated contribution of bending loss will be 1 dB at 1550 nm and 3 dB at 1625 nm for a G 657 B3 fiber!

– Influence on axial tension in fibers is NOT taken into account!

Low Optical Bend Loss Fibers

For FTTH network elements a failure probability < 10-5 over 25 years is considered acceptable, but failure rate is not constant for small bend radii over 25 years!

Reference: IEC TR 62048

What are the best design rules for fiber management systems for such fibers?

Mechanical and optical reliability concerns

Relationship between radius, stored length, bending loss and mechanical reliability.

When using the data from IEC TR 62048 the failure probability as function of the stotage radius can be calculated

Mechanical and optical reliability concerns

Relationship between radius, stored length, bending loss and mechanical reliability.

When using the bending loss performance specified in ITU-T G657 the following maximum loss estimates per fiber class (A1, A2, B3) can be made:

Mechanical and optical reliability concerns

Simplified design rules for fiber management system that stores 2 meters of fibers per splice (without axial tension):

Minimum allowed radius for given conditions:

Mechanical and optical reliability concerns

Reliability in indoor FTTH installations

- From a mechanical reliability point of view the installation rules for indoor cabling can be:

- Bend around corners: Up to 15x 90° bends around a corner with 5 mm radius.

- Staples or nails: 70x is possible when radius of fiber under staple is limited to 5 mm minimum.

- Loops of cable (over length cable) shall be made with the largest of the following 2 values: value in previous table or 10x cable diameter.

- Axial tension on cable (30% of proof strain level = max specified load for cable)

Taking the optical (loss <0.5 dB at 1550 nm) AND mechanical (failure rate<10-5per meter) limitations into account the following general cable installation rules will apply

Issues seen with bend insensitive fibers

- Some fusion splicing machines do not recognize the core of the new fibers and will not perform a core alignment (switch to cladding alignment to solve this)

- Hole assisted fiber types give problems during fusion splicing (unexpected and unpredictable deformations). Fluids may enter the holes when cleaning the fiber ends with alcohol

- Higher losses seen when different fiber types are spliced or connected together (mode field diameter mismatch with most G. 657B type fibers). Losses above 1 dB can be seen!

Low Macrobend Loss Fibers

Splicing compatibility

The selected G. 657A1 fiber from Tyco Electronics will guarantee full splice compatibility (both fusion and mechanical) with existing installed G. 652 fibers. No changes to fusion splicing parameter settings for core alignment are required.

Issues seen with bend insensitive fibers

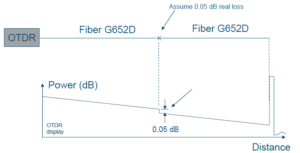

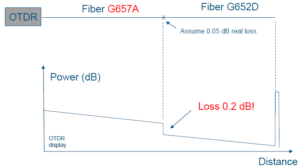

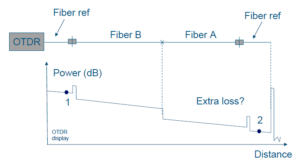

- OTDR traces will show strange effects (gainers or higher losses) when mixing fiber types in connections or splices! Non-trained installers might make wrong conclusions about the splice loss or connector loss quality!

Attenuation measurement with OTDR in lines with mixed fiber types

Bend insensitive fibers are more and more used in the distribution network. When using OTDR measurement it is necessary to take the following information into account…

Assume the following situation

Low Optical Bend Loss Fibers

Attenuation measurement with OTDR in lines with mixed fiber types

Attenuation measurement with OTDR in lines with mixed fiber types

For correct insertion loss measurements with OTDR the component or line need to be measured from both sides. The average loss will be the correct loss. This can be avoided by using the same fiber at the start and at the end of the line.

Attenuation measurement with OTDR in lines with mixed fiber types

IEC SC86A Working group 1 (fibers)

- Mainly copy of ITU-T G6xx fiber documents for the singlemode fibers, but IEC 86A is the leader for the multimode fiber specifications.

IEC cable standards

Standards for patchcord cable

- The European members of IEC SC86A(cables) and IEC SC86B(optical components) have created a Joint Working Group “Cenelec JWG 86A/86BXA” to solve interface issues between cable and optical components/closures

IEC 86A compliant cable +IEC 86B compliant connector= Non functional patchcord!

Long cable lengths tested by manufacturer do not reflect the changes on the ends of the cable, nor do they reflect the real useage with short lengths in reality.